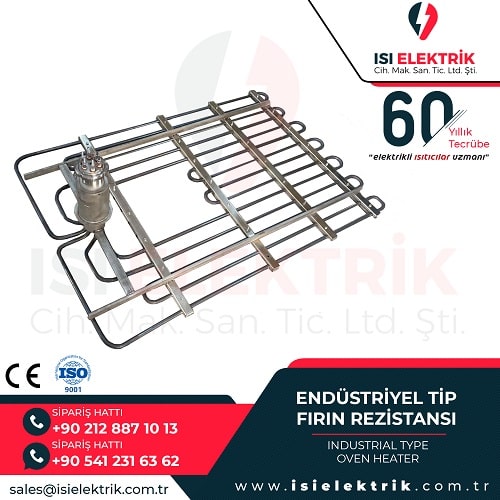

Industrial Furnace Heaters

Industrial furnace heaters are important components used in various industries to provide heating and energy efficiency. These heaters are specially designed heating elements that operate at high temperatures to raise the temperature inside the furnace to a certain level. Industrial furnaces are used in various production processes, such as heating, baking, drying, or shaping materials. In these processes, it is crucial for the heating elements to function efficiently and safely.

Industrial furnace heaters are typically produced using special alloys that offer high temperature resistance and long lifespan. These features help optimize the performance of furnaces, save energy, and reduce operational costs for businesses. Additionally, these heaters continue to operate stably despite heavy usage and extreme temperature conditions.

The applications of industrial furnace heaters are vast. They are used in many industries such as metalworking, automotive, ceramics production, plastic processing, and the food industry for high-temperature processes. For instance, processes like heating and shaping metal parts, baking ceramics, and molding plastics require the precise and efficient control of heat provided by industrial furnaces.

From a technical standpoint, industrial furnace heaters are made from materials that are resistant to high temperatures. Materials such as chromium, nickel, and aluminum are commonly used. Moreover, these heaters must be capable of continuously operating at high temperatures. Thanks to high-resistance materials, the process of converting electrical energy into heat is carried out efficiently. Furthermore, the design of industrial furnace heaters is optimized to take into account the airflow inside the furnace.

The advantages of industrial furnace heaters include high temperature resistance, long lifespan, low energy consumption, safe operation features, and easy maintenance. These features make a significant difference, especially in large-scale production facilities. To save energy, reduce operational costs, and support high-efficiency production processes, industrial furnace heaters have become an indispensable component.

When selecting industrial furnace heaters, important factors to consider include the type of material used, heating capacity, operating temperature range, energy efficiency, durability, and maintenance requirements. Choosing the right heater to suit the application needs ensures efficient and long-lasting furnace operation. Therefore, expert opinions and industry experience should be taken into account to make the right choice.

Industrial Furnace Heaters

What is an Industrial Furnace Heater?

Industrial furnace heaters are special heating elements that convert electrical energy into heat. These elements are made from materials that are resistant to high temperatures and are used in industrial furnaces, heating devices, or various heating systems. As electrical current passes through, the heater wire heats up, and this heat is effectively spread across the surrounding air or material. This process allows electrical energy to be directly converted into heat, enabling materials to reach the desired temperatures.

Industrial furnace heaters are used in many different applications. They are preferred in industries such as metalworking, ceramics production, food processing, and the automotive industry for processes that require high temperatures. For industrial furnaces to operate efficiently, the heaters used must be both durable and highly efficient. Therefore, industrial furnace heaters are typically made from alloys that have high temperature resistance, such as aluminum, nickel-chromium, and chromium.

The efficiency of industrial furnace heaters is directly related to the materials and design used. High-temperature-resistant materials ensure the longevity of the heater and allow it to operate continuously at high temperatures. Additionally, these heaters are designed to minimize energy consumption while operating efficiently. This helps industrial plants reduce costs and achieve a more environmentally friendly production process.

Industrial furnace heaters also have rapid heating capabilities, which can speed up production processes. This feature increases production efficiency and allows for quicker attainment of the desired temperature levels. Therefore, industrial furnace heaters play a critical role in industries where time is of the essence.

The maintenance and repair of industrial furnace heaters are also important. These heating elements, while maintaining high performance over long periods of use, may require occasional maintenance. Regular maintenance and replacement when necessary ensure that the furnace continues to operate efficiently.

Applications of Industrial Furnace Heaters

Industrial furnace heaters are widely used across various industries and play a significant role in each sector with their distinct applications. These heaters are highly efficient components designed to meet high-temperature requirements and optimize heating processes.

1. Metalworking Industry

The metalworking industry is one of the primary areas where industrial furnace heaters are used. In several processes where metal requires heat treatment, these heaters play a crucial role. Processes such as tempering, hardening, and heat treatment require furnaces to reach high temperatures to enhance the metal's durability and achieve the desired physical properties. The heaters used in metalworking furnaces are typically made from materials that offer high temperature resistance and energy efficiency. This minimizes energy loss during metal processing and optimizes processing times.

- Tempering: The process of cooling metal under controlled temperature and speed. Furnaces used in this process generally require high temperatures to alter the internal structure of the metal. Heaters produce heat quickly and efficiently.

- Hardening: Hardening is the process where metal is heated to high temperatures and then rapidly cooled to make it more durable. Industrial furnaces use special heaters to ensure this process occurs efficiently.

- Heat Treatment: The process where metal’s physical and chemical properties are altered through controlled heating. Heaters in furnaces help the metal reach the desired temperature for optimal properties.

2. Glass and Ceramics Industry

The glass and ceramics industry is another significant area where industrial furnace heaters are heavily used. Glass production, ceramic firing, and drying of ceramics all require high temperatures, making industrial furnace heaters indispensable in these processes.

- Glass Production: High temperatures are required to shape and bake glass. Industrial furnace heaters enable the glass to melt and take the desired shape. These furnaces provide uniform heating, enhancing the quality of the glass.

- Ceramic Firing: Firing ceramics at high temperatures hardens the material and increases its durability. Ceramic firing furnaces typically operate at high temperatures similar to those used in glass production. Heaters ensure the ceramics are fired evenly, improving quality.

- Ceramic Drying: In the production of ceramics, wet ceramics must be brought to a certain temperature level before they can be dried. In this process, industrial furnace heaters provide a fast and efficient drying process.

3. Chemical Industry

In the chemical industry, high temperatures are necessary to accelerate chemical reactions and synthesize certain chemicals. Industrial furnace heaters play an important role in generating these high temperatures. Chemical reactions generally must occur within a specific temperature range, and heaters are used to ensure these reactions take place efficiently and rapidly.

- Chemical Production: In industrial chemical production, special furnaces are used to heat chemical components and facilitate reactions. These furnaces are equipped with industrial furnace heaters to provide high efficiency.

- Petrochemical Industry: High temperatures are especially required during the processing of petroleum products. Furnaces used for the separation, processing, and refining of oil and gas rely on industrial heaters to maintain temperature control.

- Pharmaceutical Production: High temperatures are also required in the production of certain chemical compounds for pharmaceuticals. These processes benefit from the high heat performance of industrial furnace heaters.

4. Plastics and Rubber Industry

The production of plastics and rubber is an important industry for creating products in various shapes and sizes. Plastics and rubber materials are heated to high temperatures and then molded. Industrial furnace heaters are used in these thermal processes. It is crucial that heat is distributed evenly and the required temperature levels are reached during processes such as molding and baking.

- Plastic Molding: Plastics need to be heated to form products. Industrial furnace heaters provide the high temperatures necessary for the plastic to melt and take shape.

- Rubber Processing: Rubber materials are processed through a procedure called vulcanization, which requires high temperatures. Heaters quickly raise the temperatures to facilitate an efficient processing cycle during the molding process.

5. Food Industry

The food industry uses a variety of thermal processes during production. These processes require high temperatures to bake, dry, and process food products. Industrial furnace heaters are used in food production to enhance quality and ensure processing efficiency.

- Food Baking: Baking in furnaces is required for many different foods such as bread, cakes, pastries, and meat products. Industrial furnace heaters help maintain the necessary temperatures during the baking process.

- Food Drying: Drying food products increases their shelf life and facilitates transportation. Food drying furnaces are heated with industrial furnace heaters to dry the food to the desired level.

- Food Processing: The processing of meat, fish, dairy products, and other food items is also supported by industrial furnace heaters. High temperatures are crucial in ensuring food safety during these processes.

The applications of industrial furnace heaters are evident not only in the sectors mentioned above but also in many other fields. Each sector requires specific heaters designed to meet their thermal processing needs. Therefore, industrial furnace heaters are critical components that provide high efficiency, durability, and energy savings in every industry.

Technical Specifications of Industrial Oven Heaters

Industrial oven heaters are heating elements designed to provide high performance and reliability. Their technical specifications are determined according to various criteria to adapt to different industrial needs. These features help increase energy efficiency and ensure efficient execution of processes. Another important technical specification is the heating capacity. The heaters used in industrial ovens must have high power capacities. This ensures quick heating and saves time in production processes. Heaters with high power capacities can work effectively in larger ovens and heat larger materials.Energy efficiency is another critical feature of industrial oven heaters. High energy efficiency reduces energy costs for businesses by increasing the ratio of electrical energy conversion into heat. This provides an environmentally friendly solution and helps businesses reduce operational expenses. Efficient designs minimize heat loss and allow more heat to be generated with less energy.

Other technical features include durability and long service life. Industrial oven heaters are manufactured to be resistant to wear, corrosion, and high-temperature effects. This durability ensures longer use of the heater and reduces maintenance requirements. Also, with regular maintenance, these heaters can operate efficiently for a long time.

Lastly, flexibility and ease of installation are also important technical features. Industrial oven heaters can be manufactured in different sizes and shapes, making them highly flexible in adapting to various oven types and industrial processes. The installation and disassembly processes are also quite simple and quick, allowing for fast intervention in case of malfunction.

All these technical specifications make industrial oven heaters efficient, durable, and cost-effective solutions. These features also ensure that ovens perform at high levels in the long term and enable businesses to gain a competitive advantage.

1. High Heat Resistance

One of the most important technical features of industrial oven heaters is their ability to withstand high temperatures. These heaters typically operate in the range of 450°C to 1800°C, but some special designs can exceed this range. This high heat resistance allows the heaters to operate without performance loss during long-term use. Even during prolonged use in high-temperature environments, the physical and chemical properties of the alloy do not deteriorate, ensuring less maintenance and longer service life.Heaters used in industrial ovens are typically manufactured using special alloys designed to minimize the effects of high temperatures. These alloys are designed to withstand high temperatures and are also resistant to mechanical stresses. Materials such as nickel, chrome, molybdenum, and tungsten perform excellently in high-temperature environments and guarantee long-lasting operation. Additionally, these materials are highly resistant to temperature fluctuations.

High heat resistance ensures that industrial ovens operate efficiently and safely, while also saving energy. Temperature fluctuations can reduce the effectiveness of heating systems; however, heaters with high heat resistance are resistant to these fluctuations and provide a continuous and stable heating process.

Resistance to heat stress is particularly important in situations such as thermal shocks and sudden temperature changes. When ovens need to heat up or cool down quickly, the heater's ability to withstand rapid temperature changes offers a significant advantage. Heaters resistant to high heat minimize the effects of thermal shocks and allow the ovens to operate more efficiently and reliably. This feature also prevents the performance of the equipment from deteriorating over the long term.

2. Low Heat Loss

Heaters used in industrial ovens are specifically designed to minimize heat loss. Low heat loss is a critical factor in energy efficiency. Ovens are typically equipped with high-efficiency insulation materials, which minimize heat loss. Heat loss-blocking materials around the heater optimize energy consumption and minimize heat dispersion to the external environment. This improves the energy efficiency of the oven, reduces energy costs, and minimizes environmental impacts.Achieving low heat loss in industrial ovens is typically done through well-designed insulation systems. Insulation materials not only prevent heat loss but also create a more stable and efficient working environment by preventing temperature fluctuations. These materials retain the heat applied inside and minimize temperature loss to the outside, resulting in lower energy consumption.

High-efficiency thermal insulation reduces energy costs by minimizing heat loss in industrial processes. This provides a significant advantage, especially in long-term production processes. As heat loss is minimized, the overall system efficiency improves, leading to lower energy consumption and significant reductions in operating costs. This increase in efficiency not only reduces energy costs but also supports environmental sustainability.

Homogeneous heat distribution is another important feature of low heat loss. Heaters provide more efficient heat distribution, helping to maintain the same temperature level at every point. This homogeneous heat distribution ensures even heating throughout the oven, improving product quality and optimizing processing times. Additionally, this even heat distribution prevents energy loss and allows the ovens to operate more efficiently.

3. High Electrical Resistance

Another important technical feature of industrial oven heaters is their high electrical resistance values. Electrical resistance plays a significant role in ensuring that heating elements work efficiently. Electrical resistance helps generate the right amount of heat and contributes to achieving the desired temperature levels. High electrical resistance causes the wire through which the electric current passes to heat up, leading to heat dispersion into the surrounding environment. This feature supports continuous and stable heat production in industrial ovens, thereby increasing energy efficiency and generating more heat with less energy.High electrical resistance also plays a critical role in regulating heat production. The heat generated as the electrical current passes through the resistive material helps adjust the temperature levels of the heating elements. This ensures that the temperature inside the oven is maintained at the desired level. Proper adjustment of electrical resistance values is an important factor in optimizing energy efficiency and ensuring stable operation at fixed temperature levels. High-resistance materials allow for rapid attainment of desired temperature levels and maintain these levels with less energy consumption.

Additionally, high electrical resistance ensures the stable operation of the oven and enables proper completion of thermal processes. This feature helps the oven operate at a stable temperature for long periods, preventing temperature fluctuations. Stable heating ensures quality during production processes and equal processing times for products. This, in turn, increases production efficiency, minimizes energy loss, and provides a more homogeneous thermal processing cycle. High electrical resistance ensures that industrial ovens perform both efficiently and durably in the long term.

4. Production in Various Sizes and Shapes

Industrial oven heaters can be customized to meet different industrial needs. They are manufactured in various sizes and shapes to adapt to the requirements of different industrial ovens and heating systems. This diversity enables ovens to serve more specific applications. Heaters can be produced in round, rectangular, spiral, or custom designs. This design flexibility is critical for meeting different temperature and space requirements.Customizable sizes and shapes allow industrial ovens to operate more efficiently and with a more targeted focus. This feature allows heaters to be designed to meet the specific thermal requirements of each industrial application. Furthermore, every industrial oven used in industrial processes requires heater elements of specific sizes and shapes to meet particular heating capacities, heating areas, and temperature requirements. Ovens offer customized heating solutions by using heaters of different sizes for specific processing needs.

Modular designs: Many industrial ovens have the flexibility to use heaters in specific sizes and shapes. These designs can be customized to perfectly fit the requirements of a particular oven. Modular designs provide both flexibility and the ability to adapt to changing needs over time. These designs help ovens operate more efficiently and be used in different application areas.

Adaptable sizes: To be used in various production lines, heaters of different sizes are typically manufactured on-demand. This ensures that each industrial oven operates in the most efficient manner. Sizes and shapes also facilitate the installation process, allowing ovens to be set up faster and more efficiently. Adaptable heaters that cater to the constantly changing needs of industrial production lines enhance system stability and energy efficiency.

This diversity ensures that industrial oven heaters perfectly meet the temperature, heating capacity, and space requirements of all types of industrial applications. Custom sizes and shapes enhance operational efficiency and cost savings, providing high-performance and sustainable heating solutions in the long run.

5. High Electrical and Thermal Efficiency

Industrial oven heaters are designed to increase electrical and thermal efficiency, providing high performance with minimal energy consumption. This efficiency allows the production of the same amount of heat with less energy. Electrical efficiency reduces energy costs by generating more heat with less electricity, while thermal efficiency reduces heat loss and minimizes environmental impact. An efficient system not only saves on energy costs but also improves operational continuity and performance, optimizing production processes.Lower energy consumption: Since heat loss is reduced, energy is used more efficiently, leading to lower operating costs. The high-efficiency materials used in the design of heaters allow them to produce the same amount of heat while consuming less electricity. This reduces energy consumption in the long term, lowers energy bills for businesses, and creates a more sustainable production environment.

Eco-friendly design: Reduced energy consumption also helps decrease environmental impacts. This contributes to the sustainability of industrial processes. More efficient use of electrical energy helps reduce greenhouse gas emissions and environmental pollution. This makes industrial ovens an environmentally friendly solution and helps businesses reach their green energy goals.

Heat distribution optimization: Thermal efficiency not only saves energy but also optimizes the homogeneous distribution of heat inside the oven. This allows for uniform thermal treatment of products, improving product quality. At the same time, with less heat loss, lower energy consumption is achieved, which increases the overall efficiency of the system.

Long-lasting systems: High-efficiency industrial oven heaters offer long-lasting systems with less energy loss and less wear. As a result, maintenance costs are reduced, operational continuity is ensured, and a more efficient production environment is created. This leads to cost savings in the long run and allows for more efficient use of energy resources.

Industrial oven heaters, with their high electrical and thermal efficiency, reduce costs and minimize environmental impact. These features allow businesses to use more sustainable, cost-effective, and efficient heating solutions.

6. Low Thermal Expansion

Industrial oven heaters, with their low thermal expansion feature, do not experience structural deterioration even under high temperatures. This property ensures that the heaters last longer and operate reliably. Heaters are typically made from materials with very low expansion coefficients, preventing deformations caused by temperature changes. Thermal expansion can cause dimensional changes in materials under high temperature conditions, potentially leading to mechanical damage. Low thermal expansion prevents such problems, ensuring the safe and efficient operation of industrial ovens.

High durability: Low thermal expansion allows heaters to operate smoothly for extended periods. This is a critical advantage in processes that require long-term operation at high temperatures. Temperature fluctuations, especially at high-temperature levels, can cause material deformation. However, the low expansion properties minimize such deformations, thereby preserving heater performance in the long run.

Thermal shock resistance: Industrial oven heaters are resistant to sudden temperature changes. This property enables the oven to operate more efficiently and safely. The resistance of the heaters to sudden temperature changes reduces the effects of thermal shocks, saving energy and preventing potential system failures. In industrial processes, temperature fluctuations can often occur, but low thermal expansion increases the durability of heaters against these fluctuations, ensuring operational continuity.

Long-lasting operation: Low thermal expansion allows heaters to work effectively for longer periods. Changes such as expansion and contraction in high-temperature environments can cause material wear over time. However, materials with low expansion rates are more resistant to these negative effects, increasing the life span of the devices and reducing maintenance costs.

Low thermal expansion enhances the durability and efficiency of industrial oven heaters, ensuring long-term and safe operation. This feature contributes to a stable system operation against high-temperature fluctuations, supporting businesses in achieving safe and sustainable production processes.

7. Corrosion and Wear Resistance

Industrial oven heaters are made from materials resistant to corrosion and wear in high-temperature environments. This enables their use in long-term and challenging conditions. Typically, corrosion-resistant alloys are used to manufacture these heaters, which show high resistance to abrasive gases and chemicals. Corrosion and wear can be significant problems, especially in industrial ovens where temperature changes are frequent and chemical interactions are intense. However, specially designed heaters maintain their performance even under such harsh conditions.

Long life: Corrosion and wear resistance allows heaters to operate efficiently for a long time. In industrial ovens, heaters are designed for long-term, continuous use. Materials resistant to corrosion and wear extend the life of these components and minimize the effects of temperature fluctuations, chemical interactions, or other environmental factors. This property offers significant advantages in terms of both time and cost.

Reduced maintenance costs: Heaters that do not require frequent replacement due to corrosion and wear significantly reduce maintenance costs. In industrial operations, replacing and maintaining heating elements can lead to considerable time and labor losses. Corrosion and wear resistance extends the life of heaters, reducing maintenance needs and thereby lowering operational costs. Long-lasting heaters also prevent breakdowns, ensuring the continuity of production processes.

Increased chemical resistance: Corrosion and wear-resistant heaters are particularly important in industrial processes where abrasive gases, acidic environments, or chemicals are involved. High resistance to chemical compounds ensures that the heaters are less affected by environmental factors, allowing them to operate more efficiently. This is especially critical in industries such as steel production, ceramics processing, and glass manufacturing, where high temperatures and frequent chemical interactions are common.

Lower operational downtime: Corrosion and wear-resistant heaters allow businesses to experience fewer interruptions. Heaters that do not frequently fail increase continuity in production processes, helping businesses reach their targets more quickly. This leads to a more efficient production process.

Corrosion and wear resistance enhances the durability of industrial oven heaters, reduces maintenance requirements, and lowers operational costs. This property is crucial for long-term and efficient operation, providing great benefits, especially for businesses working in challenging industrial environments.

Technical Specifications of Industrial Oven Heaters

The technical specifications of industrial oven heaters vary depending on the materials used and the design. However, the most common technical parameters are as follows:

- Nominal Power: This is a measure related to the heater's production capacity and how much heat it can generate. This value determines the device's operating capacity and is optimized according to the amount of energy required for a specific application. Nominal power is usually measured in watts and represents the energy level required for the oven to operate efficiently. Power levels are determined according to the oven system's energy requirements, and the correct power selection is made to prevent overheating.

- Operating Temperature: Industrial oven heaters typically operate in temperature ranges between 300°C and 1000°C. However, some special models can be used at temperatures of 1500°C and above. The operating temperature is designed based on the thermal capacity of the material used and the needs of the oven. It is crucial to use the correct materials for heaters to ensure stable performance at high temperatures. Heater elements should be selected to withstand higher temperatures based on the operating environment of the oven.

- Resistive Material: Materials such as nickel, chromium, iron, and aluminum alloys are commonly used. These materials provide high thermal endurance and long lifespan. The type of alloy used affects the thermal conductivity and durability of the heater. Nickel-chromium alloys are often preferred because they are resistant to high temperatures and corrosion. Iron and aluminum alloys, while more cost-effective, can also yield efficient results in certain applications.

- Insulation Material: High-temperature-resistant insulation materials are used around the heater to prevent heat loss and increase efficiency. Insulation materials reduce the interaction of heating elements with the external environment, providing more efficient heat production. High-temperature-resistant insulation materials prevent overheating and ensure electrical safety. Additionally, they minimize heat loss to the outside, improving energy efficiency. Insulation materials can be selected from materials such as fiberglass, ceramic fibers, and other specialized insulating materials.

Advantages of Industrial Oven Heaters

- Energy Efficiency: Industrial oven heaters provide high thermal efficiency, minimizing energy losses. This reduces operating costs and offers an environmentally friendly solution. High efficiency enables the production of the same amount of heat with less energy consumption. This significantly reduces energy bills for businesses while ensuring a more sustainable production process. Additionally, increased energy efficiency contributes to a smaller carbon footprint.

- Long Lifespan: Made with high-quality materials, these heaters can operate for many years without issues, reducing maintenance and replacement costs. The long lifespan of industrial oven heaters eliminates the need for frequent reinvestment. Additionally, continuous industrial processes are maintained because the maintenance intervals for these systems are longer, minimizing operational interruptions.

- Fast Heating and Cooling: Industrial oven heaters can heat up quickly and reach the desired temperature. Their rapid cooling feature also increases efficiency in production processes. This feature enables shorter production cycles and enhances labor productivity. Furthermore, quick cooling helps prevent material degradation and quality loss caused by temperature fluctuations, ensuring more consistent products.

- Low Maintenance Requirements: Due to their high durability, industrial oven heaters have very low maintenance requirements. These heaters are suitable for long-term use even in high-temperature and challenging environmental conditions, extending maintenance intervals. This prevents businesses from losing time and labor on frequent maintenance. Low maintenance requirements reduce maintenance costs while also providing additional benefits for workers' job safety.

- Adaptability to Various Applications: Industrial oven heaters can be designed to fit various applications in different industries. These heaters can be customized according to needs and are used in sectors such as automotive, metal processing, ceramics manufacturing, food processing, and many more. This flexibility allows ovens to be efficiently used in different production lines or special needs.

Technical Details to Consider When Selecting Industrial Oven Heaters

When selecting industrial oven heaters, several key technical details must be considered. These details play a critical role in both safety and efficiency, and making the right choice ensures long-term, trouble-free operation. Below are the important technical factors to keep in mind when making this selection:

- Operating Temperature: The temperature range at which the heater will operate should align with the temperature requirements of the area where it will be used. Industrial ovens can operate within different temperature ranges, so the heater must meet the temperature limits of the environment. Additionally, some ovens experience sudden temperature fluctuations and thermal shocks, so the heater must be durable enough to withstand these conditions. A heater with an incorrect temperature range can negatively affect the oven's efficiency or lead to early failure.

- Power Capacity: The amount of power required should be accurately determined. Otherwise, overheating or insufficient heating can occur. Correctly calculating power capacity ensures the oven reaches and maintains the desired temperature efficiently. Power capacity also helps manage energy consumption effectively. The power value helps maintain a consistent and safe temperature level during the oven's long-term operation.

- Material Selection: The material used to manufacture the heater should be suitable for its intended use. For high-temperature applications, durable alloys should be chosen. The material used impacts both the heating capacity and the durability of the heater. High-quality alloys increase heat resistance while preserving the material's physical and chemical properties over time. This prolongs the oven's life and reduces maintenance needs. Material selection also affects the heater's resistance to corrosion and wear.

- Size and Shape: The heater should be appropriately sized and shaped to fit the installation area for efficient use. Each industrial oven has a unique design, so the heater must be properly sized to fit the space. Modular designs, particularly those that can be used in various settings, make heaters much more versatile. Additionally, the correct size and shape help the heating elements distribute heat evenly and efficiently. Depending on the installation area, round, rectangular, or custom-shaped heaters may be selected.

Energy Savings with Industrial Oven Heaters

Industrial oven heaters play a crucial role in energy savings. These heaters are highly efficient heating elements that offer significant advantages in reducing energy costs for businesses. Their designs ensure high thermal efficiency, producing more heat with less energy consumption. Advanced technologies used to minimize heat loss further maximize energy savings and reduce environmental impact. Properly selected heaters not only increase energy efficiency but also enhance operational efficiency, creating a more sustainable production process.

Features Ensuring High Thermal Efficiency

Industrial oven heaters are equipped with several features that ensure high thermal efficiency. These features not only help save energy but also contribute to more efficient and environmentally friendly business processes:

- Low Heat Loss: Industrial oven heaters are designed with special insulation materials that minimize heat loss. These materials ensure that heat is retained only in the required areas, preventing heat from spreading to the outside. Improved insulation quality allows businesses to significantly reduce energy consumption. Minimizing heat loss means less energy is used, directly leading to lower energy costs.

- High Heat Retention Capacity: Industrial oven heaters are made from materials with high heat retention capacity. This feature ensures that heat within the oven is retained for long periods and efficiently distributed. High heat retention helps the oven heat up and cool down quickly, making production processes more efficient. When the temperature inside the oven remains stable, processing times are shorter and energy losses are reduced. Additionally, the ovens use energy more efficiently as less energy is required to reach the desired temperature in the heated environment.

- Fast Heating and Cooling: Industrial oven heaters have the ability to heat up and cool down quickly. This feature allows the oven to reach the desired temperatures in a shorter time, particularly beneficial for production processes. Fast heating and cooling reduce energy losses as the oven uses less energy to achieve the required efficiency in less time. Furthermore, rapid cooling ensures that the oven's temperature decreases quickly after the process, requiring less energy for cooling. This feature is especially useful in high-capacity production facilities, providing substantial energy savings.

Industrial oven heaters play a critical role in many industries. These heaters directly impact the performance of industrial ovens, enhancing the efficiency of production processes. With benefits such as high thermal efficiency, long lifespan, and low energy consumption, they have become essential elements of modern production systems. Particularly in today's environment of rising energy costs, properly selected industrial oven heaters can provide substantial savings for businesses. Moreover, effective temperature control in thermal processes improves product quality and reduces production times. Industrial oven heaters not only ensure high efficiency but also offer environmentally friendly solutions, contributing to sustainable production processes. When selected with attention to the correct technical details, these heaters become a vital tool for energy savings and minimizing environmental impact. Their long lifespan reduces maintenance costs and ensures continuous oven operation. Additionally, proper material and design choices offer flexibility to meet various industrial needs. Paying attention to the correct technical details when selecting industrial oven heaters is crucial for energy savings and efficiency. Factors such as operating temperatures, power capacity, material selection, size, and shape are decisive elements for long-term efficiency and low operational costs. Therefore, selecting the most suitable type of heater for each oven and ensuring its proper installation is essential.

Frequently Asked Questions

Industrial Oven Resistances