Asphalt & Bitumen Heaters

Asphalt & bitumen heaters are specialized heating elements that ensure optimal temperature control during the production, transport, and application of asphalt and bitumen. They help maintain the material at the desired fluidity while protecting the performance of machinery and equipment. As a result, they improve application quality and minimize both material loss and labor time.

Designed to withstand high temperatures, asphalt and bitumen heaters are manufactured to operate reliably under harsh industrial conditions, offering long service life. They maintain ideal heat levels in asphalt production plants, mixers, transfer lines, storage tanks, and road construction machines, enabling uninterrupted operations. Their energy-efficient structure also contributes to reducing overall operational costs.

With easy installation and maintenance, these heating elements provide a user-friendly solution, available in various sizes, power ratings, and connection options to suit different asphalt and bitumen equipment. Compliant with industrial safety standards, they play a key role in achieving faster, safer, and more efficient asphalt applications.

Asphalt & Bitumen Heaters

Asphalt machine heaters are special heating elements that increase system efficiency by providing optimum temperature control during asphalt production and application processes. With their high temperature resistance, long service life, and energy efficiency, they are an indispensable part of asphalt machines.

Product Introduction

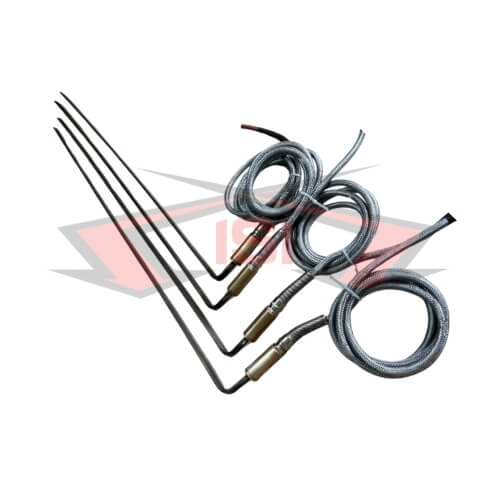

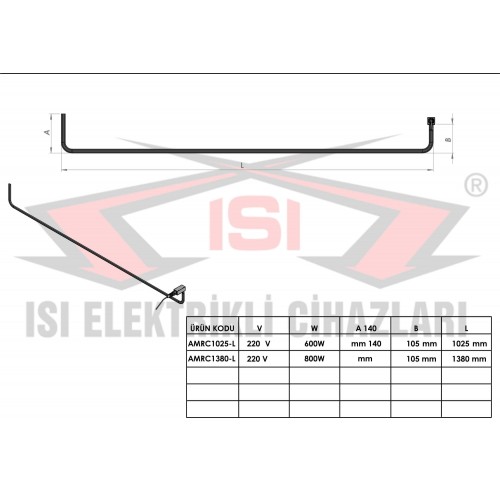

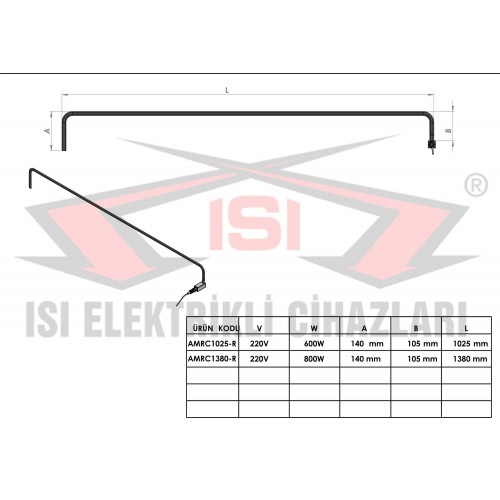

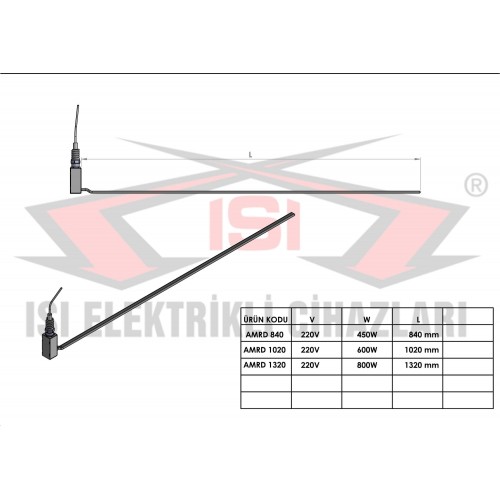

Heaters used in asphalt machines ensure the ideal heat level to maintain the fluidity of bitumen and the mixture during mixing, transportation, and pouring processes. In addition to standard tubular heaters, flat-section heaters used in forged nozzles (nozzle areas) provide excellent performance in areas requiring high heat density.

These special flat heaters minimize heat loss in the machine nozzle, allowing the material to be processed more easily. At the same time, thanks to their compact structure, they can be easily installed in narrow areas.

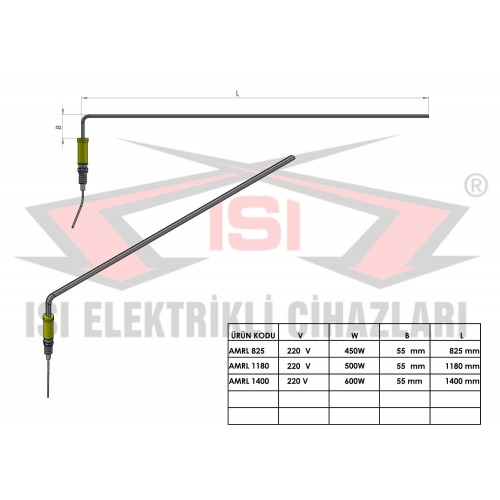

Technical Specifications

- Voltage: 220V / 380 or production based on special requirements

- Power Range: 100W – 5 MW

- Material: Stainless steel body, Nickel-Chrome (NiCr) resistance wire

- Operating Temperature: 0°C – 450°C

- Insulation Material: MGO (Magnesium Oxide) high thermal insulation

- Connection Types: Flanged, threaded, tubular or flat-section mounting

- Special Application Type: Flat-section heaters for forged nozzles

- Protection Class: IP65 optional production

Application Areas

- Asphalt plants

- Forged-nozzle asphalt machines

- Bitumen tanks and heated pipe lines

- Mixing systems

- Melting and storage tanks

Advantages

- Homogeneous heat distribution and high heating efficiency

- Optimum heat transfer in forged nozzle areas

- Energy-saving design

- Long service life and durable material structure

- Easy installation and maintenance

- Flexible production with customized size, power, and section design

Technical Details of Asphalt Bitumen Heaters

The technical capacity of heating elements directly affects process continuity and final application quality. Heat transfer speed, heater wire properties, insulation material durability, protection class, and connection type must be selected based on project requirements.

NiCr heating wire for high-temperature resistance, MGO insulation for minimal heat loss, and stainless-steel housing ensure safe and long-lasting performance. For harsh field environments, additional protection such as IP65 offers increased durability.

Key Considerations When Selecting Asphalt Bitumen Heaters

- Operating Temperature: Correct heat level must be selected based on application needs.

- Machine & installation compatibility: Tubular or flat section? Proper sizing is essential.

- Energy Efficiency: Prefer heaters that provide high heat output with low consumption.

- Insulation Quality: MGO or enhanced insulation is recommended.

- Material Strength: Stainless, corrosion-resistant structure is essential.

- Power Range Selection: Proper watt or MW sizing should be calculated.

- Protection Rating: IP65 may be required for outdoor exposure.

- Custom Geometries: Narrow areas may require special flat-section models.

Attention to these factors ensures long service life, high performance, and extended fault-free operation.

Energy Saving with Asphalt Bitumen Heaters

Energy consumption represents a major portion of asphalt production costs. Using heaters designed for high energy efficiency not only reduces operational expenses but also supports environmental sustainability. With correct power sizing, optimized geometry, and advanced insulation, asphalt mixing durations are shortened and operational cycles run more efficiently, reducing overall energy usage.

Poor insulation, low-quality heater components, and inadequate heat transfer are some of the primary causes of excessive power usage. Energy-efficient heaters ensure that heat is transferred directly and evenly to the material, preventing wasted energy and improving material flow.

- Fast heat-up time: Minimizes delay before operation begins.

- Proper insulation: Prevents heat loss and unnecessary power consumption.

- Uniform heat distribution: Prevents localized cooling and flow issues.

- Smart power control: Automation integration enables demand-based heating.

- Thermostat & sensor systems: Protect against overheating and excessive consumption.

- Optimized watt density: Prevents over-sizing and reduces operational cost.

With these performance improvements combined, continuous-operation asphalt facilities can benefit from 15–35% energy reduction annually. Lower energy consumption also reduces carbon emissions, supporting eco-friendly production.

In summary, properly selected and positioned asphalt bitumen heaters provide long-term economic gain while enabling cleaner and greener production.

Recommendations to Improve Asphalt Bitumen Heater Performance

Proper heater selection alone is not enough to achieve maximum efficiency. Installation quality, maintenance planning, power optimization, and environmental considerations all affect heater lifespan, reliability, and heat output. The following best practices help ensure safe and efficient operation:

- Regular maintenance: Remove asphalt and bitumen residues to prevent overheating and oxidation.

- Professional installation: Poor mounting can cause stress and premature failure.

- Enhanced insulation: Supports energy preservation through reduced heat loss.

- Voltage compatibility: Electrical system must support heater load requirements.

- Automation controls: Enables efficient energy management and consistent heating.

- Dust/moisture protection: IP65 protection improves resistance in open-field conditions.

- Accurate power calculations: Prevents excessive energy consumption or inefficient heating.

- Dimensional compatibility: Length or shape should match heating zone requirements.

With these engineering practices, heater lifespan can increase 2–3 times while operational interruptions significantly decrease. Early problem detection through performance monitoring ensures reliable production and reduced repair costs.

Asphalt Bitumen Heaters

Asphalt bitumen heaters are the key to high-quality asphalt production workflows. They maintain bitumen fluidity, eliminate heat loss during transport and paving, and ensure maximum productivity with minimum waste.

Flat or tubular heater designs developed using modern engineering techniques deliver uniform heating, superior energy efficiency, and seamless integration into machinery layouts. The resulting reduction in energy consumption translates into strong competitive advantage.

Stainless steel construction, NiCr heater wire, and advanced insulation technologies reduce maintenance needs, extend operating lifespan, and guarantee continuous production flow.

When heating systems are properly selected and installed, asphalt bitumen heaters:

- Reduce operational costs

- Improve energy efficiency

- Increase quality consistency

- Prevent downtime and unexpected failures

- Minimize environmental impact

Ultimately, asphalt bitumen heaters stand out as the most effective and reliable heating solution for businesses seeking high performance, operational durability, and long-term energy efficiency in asphalt production.

Asphalt Bitumen Heaters

Asphalt bitumen heaters are core heating solutions that ensure ideal temperature levels throughout asphalt production and application processes. Maintaining the fluidity of bitumen and asphalt mixtures guarantees both operational efficiency and final product quality during mixing, transport, and paving. Properly selected and professionally installed heater systems provide consistent material flow and reduce production losses by preventing cooling throughout the process.

In asphalt plants and field applications, heat control is the most critical factor affecting production performance. In this context, asphalt bitumen heaters are not only heating components; they are strategic devices that support operational efficiency, sustainability, and system reliability. Today, due to increasing competition, companies must maximize production output while minimizing energy consumption. Therefore, energy-efficient heater technologies have become an indispensable investment in the asphalt industry.

Why Is Heat Management Critical?

Bitumen rapidly solidifies at low temperatures and chemically degrades at excessively high temperatures. For this reason, precise temperature control is mandatory during production, storage, transportation, and paving stages.

Low temperature results in:

- Loss of material fluidity

- Machine clogging and stoppages

- Reduced surface coating quality

Excessive temperature results in:

- Thermal decomposition of bitumen

- Increased emission and environmental risks

- Unnecessary energy waste

- Higher carbon footprint

In conclusion, asphalt bitumen heaters ensure **optimal heat with minimum energy**, preserving both quality and sustainability.

The Role of Heaters in Asphalt Production Cycle

Every phase of asphalt production is directly affected by heat management. Asphalt bitumen heaters provide uninterrupted flow and homogeneity in the following systems:

- Bitumen storage tanks: Prevent material solidification

- Mixing systems: Ensure mixture uniformity

- Pipeline transfer: Maintain fluidity during transport

- Paving and spraying machines: Improve laying quality

- Nozzle applications: Prevent cooling in high-risk narrow areas

Together, these functions deliver continuous operation and high production efficiency.

Working Principle of Asphalt Bitumen Heaters

Asphalt bitumen heaters operate by converting electrical energy into heat through high-resistance NiCr heating wires located inside the heater structure. When electrical current passes through these wires, controlled heat is generated and transferred efficiently to the bitumen-contacting surfaces. The heat produced is retained and guided outward through high-performance MGO (Magnesium Oxide) insulation, ensuring maximum thermal efficiency and safety.

Modern heaters are equipped with intelligent control and sensor systems. These systems analyze temperature data in real time and automatically regulate power output. This eliminates overheating risks, reduces unnecessary power consumption, and maintains stable temperature levels throughout the entire process.

The Importance of Design in Heat Transfer

Every asphalt application has its own heat requirement profile. Therefore, heater design must be optimized according to the following factors:

- Watt density

- Surface contact area

- Insulation type and thickness

- Heat distribution uniformity

- Mechanical adaptability

For example, wider-surface tubular heaters are preferred in tanks, while specially manufactured flat heaters are used in restricted nozzle areas where thermal intensity must be high.

Economic Effects of Heat Loss in Asphalt Production

Incorrect heat management leads not only to quality degradation but also to significant financial losses. Undetected heat loss in asphalt plants may result in:

- Increased energy consumption and operational costs

- Mixture deterioration causing wastage

- Equipment overload leading to breakdowns

- Delays in project deadlines and labor inefficiency

When heaters are improperly sized or inefficiently installed, production costs can increase dramatically and reduce profitability over time.

The Role of Asphalt Bitumen Heaters in Energy Efficiency

Energy efficiency is a fundamental performance criterion in today's asphalt industry. Asphalt bitumen heaters provide high energy savings through the following mechanisms:

- Smart power control: Heaters work only when necessary, eliminating idle consumption.

- Rapid heat-up capability: Reduces start-up times and accelerates production.

- Enhanced insulation: Minimizes heat escape and optimizes heating cycles.

- Uniform heat distribution: Prevents localized heat zones that force excessive consumption.

With these improvements, mixing efficiency can increase by 10% to 25%, strengthening both production capacity and sustainability goals.

Industrial Application Spectrum of Asphalt Bitumen Heaters

Asphalt bitumen heaters are used across a wide range of industrial operations, not only in asphalt plants:

- Asphalt production plants

- Bitumen storage and melting tanks

- Heated transfer pipelines and pumping systems

- Road paving and spraying machines

- Thermal oil heating systems

- Mobile asphalt transport units

- Road maintenance and patching equipment

This diversity shows that heaters must be compatible with various mechanical and environmental working conditions.

Modern Heater System Technologies

Advancements in digital technologies have significantly improved the durability and energy performance of heater systems in asphalt operations. Current generation asphalt bitumen heaters feature:

IoT-Based Monitoring and Control

Remote temperature tracking, live performance analytics, and alarm signaling enable predictive maintenance and efficiency improvements.

Corrosion-Resistant Structural Materials

Provides long-lasting performance against aggressive chemical effects of bitumen.

High-Precision Sensor Supported Heat Management

Temperature accuracy within ±1°C ensures stability and reduces material degradation risks.

Energy Optimization Algorithms

Automatically adjusts power output based on production demand and heat cycles.

These technological developments create a more productive, controlled, and safer manufacturing environment.

Common Failures in Asphalt Bitumen Heaters and Their Solutions

Due to continuous heavy-duty operation, asphalt bitumen heaters may experience failures over time. These failures generally arise from incorrect power selection, insufficient insulation, improper mounting, or chemical exposure. However, with proper maintenance and engineering, they can be prevented or eliminated before affecting production.

Most Common Failure Types

- Breakdown of resistance wire caused by overloading or voltage imbalance

- Uneven heating zones due to insulation loss or internal structural issues

- Deformation of heater housing due to mechanical stress or improper installation

- Moisture and chemical ingress in low-rated IP protection heaters

- Temperature sensor malfunction resulting in incorrect thermal feedback

Impact of Failures on Production

These failures can lead to severe operational losses:

- Unplanned downtime and stoppages

- Quality reduction in asphalt mix

- Increased energy consumption

- Delays in job delivery and labor inefficiency

Professional Solution Strategies

- Periodic inspection using thermal imaging cameras

- Load balancing through power analyzers

- Selection of IP65 or higher protection classes

- Replacement with OEM-compliant spare parts

- Sensor redundancy and advanced temperature control

With these strategies, heater lifespan can be extended by up to 3 times, while operational reliability significantly increases.

Heater Selection Guide for Asphalt Applications

Each system has unique heat demand characteristics. Therefore, the following professional criteria must be evaluated during heater selection:

1. Technical Parameters

- Operating temperature range

- Watt density (W/cm²)

- Voltage level (220V / 380V)

2. Mechanical Compatibility

- Dimensional construction and mounting method

- Suitability for tubular or flat design

- Flexibility requirements in cramped spaces

3. Environmental Conditions

- Corrosion exposure level

- Moisture contact risk

- Outdoor temperature fluctuations

4. Energy Efficiency

- Insulation quality

- Automation and sensor compatibility

- Power demand response controls

This checklist ensures a zero-risk investment decision and long-term efficiency.

Maintenance Plan: The Foundation of Continuous Operation

Although heaters can operate for long durations without intervention, neglecting maintenance significantly increases failure risk. A structured maintenance plan must always be followed.

Recommended Maintenance Schedule

- Weekly: Surface cleaning and residue removal

- Monthly: Resistance value measurement

- Quarterly: Insulation tests and mounting check

- Annually: Sensor calibration and full performance audit

Compliance with this schedule reduces unexpected breakdowns by up to 90 percent.

Smart Heat Management in Asphalt Production

With Industry 4.0 advancements, heaters are now transformed into intelligent sensor platforms connected to digital ecosystems. IoT-based heat management provides:

- Real-time monitoring of process temperature

- Energy consumption analytics

- Remote control and early-warning features

- Automated power optimization cycles

These digital controls can deliver up to 30 percent improvement in productivity metrics while enhancing operational safety.

Flat-Type Heaters: The Hidden Champions of Nozzle Applications

Nozzle zones are among the most critical locations in asphalt operations. Bitumen cools rapidly in this region, leading to flow loss and blockage. Flat heaters solve this problem by:

- Transferring heat effectively in narrow areas

- Ensuring rapid fluid recovery

- Minimizing heat escape

- Maintaining continuous asphalt flow and material distribution

For these reasons, flat-type heaters have become the industry standard in modern asphalt machinery.

Sustainability Perspective on Heater Usage

With tightening global environmental regulations, asphalt plants are increasingly expected to reduce emissions and adopt energy-efficient solutions. Asphalt bitumen heaters contribute significantly to sustainability targets by:

- Lowering carbon emissions by up to 20 percent

- Reducing total energy consumption

- Preventing unnecessary waste of heated bitumen

- Reducing maintenance waste and material fatigue

Sustainable heater technology is no longer a competitive advantage but a mandatory requirement for asphalt manufacturers worldwide.

Comparison of Different Heater Types in Asphalt Industry

Each heater type delivers unique advantages depending on production design, required thermal intensity, and installation area. The main heater types used in asphalt operations are:

1. Tubular Heaters

- High durability in large mounting surfaces

- Long operational life

- Ideal for bitumen tanks and large mixers

2. Flat-Type Heaters

- Fast, intense heating capabilities

- Perfect fit in limited nozzle regions

- Custom-designed per machine model

3. Flanged Heaters

- Easy removal for maintenance

- High mechanical safety

- Preferred in steel storage tanks

4. Heating Cables

- High flexibility and universal application

- Suitable for external pipeline heating

- Lower watt density than tubular or flat types

Correct type selection ensures optimized lifetime cost and performance.

Thermal Dynamics in Bitumen Heating

Bitumen is highly viscous and has a slower response to heat transfer. Therefore, thermodynamic efficiency must be maximized to prevent temperature gaps within the mixture.

Thermal Factors That Must Be Calculated

- Thermal conductivity coefficients

- Watt density per cm²

- Heat retention time of insulation

- Ambient temperature loss factors

Incorrect watt density causes overheating, oxidation, and reduced heater life, while insufficient watt density slows production.

Case Studies from Real Production Sites

Case 1 – Solidification in Bitumen Tanks

A plant experienced frequent downtime due to cold zones within tanks.

- Solution: Combination of tubular and flat heaters

- Outcome: 27 percent capacity increase

Case 2 – Nozzle Blockage

Cooled bitumen obstructed flow in the paving machine.

- Solution: Flat heaters with temperature-feedback control

- Outcome: Zero blockage and 32 percent energy savings

Case 3 – Excessive Energy Costs

- Solution: Watt optimization, MGO insulation, automation

- Outcome: Annual savings over 150,000 TRY

These examples prove the value of heater engineering in operational profitability.

Standards and Certification in Heater Technology

Reliability, safety, and compliance are key to heater performance. Therefore, heaters must follow internationally validated standards:

- CE – European health and safety compliance

- IEC – Electrical protection and insulation regulations

- ISO 9001 – Quality management assurance

- ATEX – Safety in hazardous environments

Non-certified products pose severe electrical and operational risks.

Cost Efficiency Analysis: Return on Heater Investment

ROI analysis shows that a heater upgrade typically pays for itself in a short time due to energy savings and reduced maintenance costs.

- Average ROI period: 6–12 months

- Full maintenance savings: within 3 years

Companies seeking competitive advantage gain substantial financial benefits with the right heater solution.

Ideal Installation Strategy for Asphalt Bitumen Heaters

The installation process has a direct impact on heater performance and lifespan. Even a top-quality heater will underperform if it is poorly installed. Therefore, professional installation procedures must be followed to ensure maximum heat transfer efficiency and operational safety.

Professional Installation Steps

- Accurate placement plan based on thermal distribution

- Mounting without applying excessive mechanical force

- Routing cables to prevent exposure to chemicals and sharp edges

- Using thermal compound to improve heat conduction efficiency by up to 30 percent

- Heat mapping and calibration before commissioning

Proper installation guarantees that the heater operates under ideal engineering conditions from the first day.

Sensor Placement Recommendations

Temperature sensors play a critical role in heater control. Incorrect sensor positioning may lead to false temperature readings and overheating events. Best practices include:

- Locating sensors at the point where heat drops last

- Placing them near the highest watt-density region

- Positioning them in potential hotspots where overheating may occur

These principles ensure accurate monitoring and consistent heating performance.

Occupational and Operational Safety Protocols

Bitumen is a flammable and chemically sensitive material. Thus, heaters must be operated under strict safety conditions. Safety protocols include:

- Heater housings must remain spark-free during operation

- Grounding must be inspected regularly

- Temperature protection systems must never be bypassed

- Over-temperature protection fuse must always be active

- Emergency shutdown switches must be accessible at all times

These measures protect both machinery and personnel against hazardous incidents.

Heat Loss Calculations for Proper Power Selection

Correct heater sizing requires calculating expected heat loss based on engineering data. Heat loss depends on:

- Tank volume and exposed surface area

- External ambient temperature variations

- Type and thickness of insulation material

- Viscosity and heat capacity of bitumen

- Length and exposure of transfer pipelines

With correct heat loss modeling, production output becomes predictable, and overall energy consumption stabilizes.

Example Heat Loss Scenario

A 1000-liter tank that must maintain 160°C temperature with a surrounding temperature of 15°C experiences approximately:

- 1.8 to 2.3 kW heat loss

This demonstrates that improper sizing can drastically increase operational costs and downtime.

Frequently Made Errors in Heater Usage

Many heater failures are caused by operational mistakes rather than product defects. Common user mistakes include:

- Incorrect watt density selection

- Disabling temperature control systems

- Stress applied on heater casing during installation

- Leaving air pockets inside tanks

- Ignoring grounding issues

Such mistakes reduce heater lifespan significantly while increasing production disruptions.

Extending the Lifespan of Asphalt Bitumen Heaters

Proper use and scheduled maintenance significantly increase heater lifespan. When best-practice maintenance methods are applied, heaters can operate three times longer with improved reliability.

Recommended Lifespan Improvement Techniques

- Using thermal compound to enhance heat transfer efficiency by 30 percent

- Integrating sensor-controlled protection systems

- Monitoring overheat limits through additional control circuits

- Regularly checking and tightening electrical connections

- Replacing insulation materials before degradation occurs

- Maintaining a clean tank environment to avoid residue buildup

With systematic maintenance, annual equipment failure can be reduced by up to 80 percent.

Correlation Between Heat Management and Final Asphalt Quality

Incorrect heating conditions lead to chemical degradation of bitumen. This results in weakened road surfaces and drastically shorter road life.

Consequences of poor heat control include:

- Lower bonding performance

- Reduced load-bearing capacity

- Cracking and delamination risks

- Decreased durability and safety

Therefore, heat control is not only an operational factor but also a critical quality determinant.

Future Heating Technologies in the Asphalt Industry

A new generation of heater systems is emerging with rapid advancement in digital and automation technologies. Trends that will shape the industry in the next decade include:

- Artificial intelligence-based thermal prediction and automatic control

- Cloud-based energy monitoring with real-time alerts

- Complete thermal mapping for precise zone management

- Self-diagnostic heaters with predictive maintenance indicators

- Carbon-neutral heating energy sources

Technology-driven heat control will redefine sustainability and competitive advantage in asphalt production.

ERP and SCADA Integration in Asphalt Heating Systems

Asphalt bitumen heaters are now part of a wider digital ecosystem integrated with plant management software. This integration supports:

- Automated process flow

- Production performance optimization

- Remote alarming and supervisory control

- Instant response to power fluctuations

ERP and SCADA connectivity contributes to operational transparency and increased efficiency.

Checklist for Asphalt Plant Managers

To ensure maximum efficiency and minimum operational cost, plant managers should review the following checklist regularly:

- Heater type correctly selected?

- Watt density calculations performed correctly?

- Grounding system tested regularly?

- IP protection rating suitable for outdoor exposure?

- Maintenance performed as scheduled?

- Energy reports monitored and analyzed?

A disciplined checklist approach protects business continuity and investment value.

Importance of Selecting the Right Supplier

Heater quality depends not only on manufacturing but also on engineering know-how and support capabilities of the supplier.

Characteristics of a Qualified Supplier

- Verified sector experience and strong references

- Technical consultation and customized heater design

- Availability of OEM-compatible spare parts

- Rapid emergency assistance and maintenance services

- Products complying with CE, IEC, ISO standards

Reliable suppliers ensure long-term success and risk reduction.

Ultimate Performance Recommendations for Job Sites

The following best-practice guidelines maximize asphalt heater efficiency and material integrity:

- Do not begin mixing until thermal stability is achieved

- Match mixing cycle duration to heat distribution rate

- Improve pipeline insulation to reduce thermal losses

- Use flat heaters on nozzles to prevent rapid cooling

- Perform monthly thermal imaging checks

Minor improvements in heat management lead to exponential gains in quality and resource efficiency.

Competitive Advantages Provided by Asphalt Bitumen Heaters

To stay competitive, asphalt facilities must deliver faster, higher-quality production at lower costs. High-efficiency heaters provide:

- Time advantage through faster production

- Cost advantage through reduced energy use

- Quality advantage through consistent heating

- Reputation advantage through improved customer satisfaction

In short: better heating equals stronger market positioning.

Energy Management: Measure, Analyze, Improve

Energy performance plays a direct role in operational profitability. Efficient heat management requires the following cycle:

- Generate a heat map of the system

- Analyze sensor-based energy data

- Optimize heat cycles and power demand

- Continuously report and improve performance

A data-driven approach ensures continuous improvement and reliable production economics.

Asphalt Bitumen Heaters

Asphalt bitumen heaters are decisive components in ensuring quality, efficiency, and operational reliability throughout the asphalt production chain. When heaters are correctly selected, mounted, and maintained, businesses benefit from:

- Lower operating and energy costs

- Increased production speed and capacity

- High and consistent material quality

- Extended machine and heater lifespan

- Improved environmental and worker safety

Ultimately, successful asphalt production is built on effective heat control. Professional heater selection guarantees a sustainable competitive advantage in the industry, ensuring profitable and reliable operations for years to come.

Frequently Asked Questions