Heater Stone

Heater stone is a component widely used in electrical devices to generate heat. These stones are one of the main building blocks of heating devices and are typically made from metal alloys. When electrical current passes through the heater stone, heat is generated due to the resistance. This process of converting electrical energy into heat allows electric heaters and other heating devices to operate efficiently.

The operating principle of heater stones is quite simple: As the electric current passes through the stone, it resists, and as a result, the stone heats up. This heat can be focused in a specific part of the device, allowing the desired temperature to be reached. Heater stones are found in many everyday devices such as electric heaters, water heaters, electric stoves, and ovens. These stones ensure that heat is distributed correctly and allow users to achieve the temperature they need.

Heater stones are generally made from durable and long-lasting materials. In addition to metal alloys, some special ceramic materials can also be used. These stones are not only resistant to high temperatures but also provide safe usage. Designed to ensure proper functioning of electric devices, heater stones offer an efficient heating experience for users.

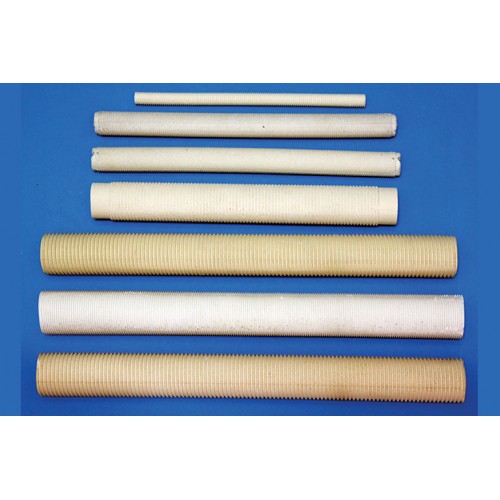

Heater Ceramics

Heater ceramics are special materials used as heating elements to provide high resistance at high temperatures. These ceramics are widely preferred in industrial applications that require high temperatures. These materials, which are resistant to high temperatures, are typically used as heating elements in industrial devices and play a critical role in various sectors.

Heater ceramics are usually made from materials like alumina, magnesium oxide, and zirconium oxide. These materials enable the ceramics to show higher resistance at high temperatures, and when used as heating elements, they remain durable for a long time. In industrial applications, they are commonly used in metal casting, the chemical industry, and the automotive sector. They also play an important role in sterilizing surgical equipment, energy production, and the electronics industry.

These ceramics are preferred in applications that require energy efficiency due to their ability to withstand high temperatures. In addition to being used as heating elements in electronic devices, heater ceramics can also be used to accelerate chemical reactions. In the metal casting industry, these ceramic materials perform an essential function in providing the necessary temperatures for shaping and processing metal parts.

Heater ceramics are indispensable in many industrial applications that require high temperatures. These materials are highly efficient in heat production and transfer, and as technology advances, they continue to gain improved features. Therefore, these materials play an important role both in our daily lives and in industry.

Galvanic Bath

Selection of Resistance Ceramics

Resistance ceramics are materials with high resistance at high temperatures. They are commonly used in electric vehicles, industrial processes and power generation plants. Some points to consider when choosing resistance ceramics are as follows:- Temperature Range: Resistance ceramics can work in certain temperature ranges. The ceramic material you choose should be higher than the temperature range required.

- Mechanical Strength: Resistance ceramics should have high mechanical strength. Because these materials are used in industrial environments and can be exposed to high mechanical stresses.

- Chemical Resistance: Resistance ceramics can come into contact with chemicals, therefore, their chemical resistance must be high.

- Thermal Conductivity: Resistance ceramics should have high thermal conductivity. This allows the ceramic material to conduct heat quickly and dissipate heat more effectively.

- Electrical Resistance: Resistance ceramics must be of high electrical resistance. This ensures low losses and low energy expenditure of the ceramic material while conducting electric current.

What are the Advantages of Resistance Ceramics?

Resistance ceramics have many advantages. These may include:- High temperature resistance: Resistance ceramics can operate at very high temperatures and therefore have a wide range of uses in industrial environments.

- Mechanical durability: Resistance ceramics have high mechanical strength and can therefore be used in high-stress environments.

- Chemical resistance: Resistance ceramics can come into contact with chemicals and therefore their chemical resistance is high.

- Thermal conductivity: Since resistance ceramics have high thermal conductivity, they can transmit heat quickly and dissipate heat more effectively.

- Electrical resistance: Since resistance ceramics have high electrical resistance, they have low losses and low energy consumption while conducting electric current.

- Durability: Resistance ceramics are very durable and have a long life.

- Environmentally friendly: Resistance ceramics do not contain toxic substances and do not harm the environment.

Types of Resistance Ceramics

Resistance ceramics can be produced in different varieties and this variety depends on factors such as the chemical composition of the material, its structure and production method. For instance;Alumina (Al2O3) ceramics: They are known for their high thermal resistance, electrical conductivity and mechanical durability.

Zirconia (ZrO2) ceramics: are known for their high thermal resistance, electrical conductivity and mechanical durability.

Silicon Carbide (SiC): ceramics are known for their high thermal resistance, high mechanical strength and electrical conductivity.Steatite (MgO) ceramics: It is known for its high thermal resistance, mechanical durability and electrical conductivity properties.

Mullite (3Al2O3.2SiO2) ceramics: Known for their high thermal resistance, mechanical durability and electrical conductivity.Heater Working Principle

The working principle of heaters relies on serving as a resistance element through which electric current passes. Heaters are typically made of long, thin wires or elements composed of metal alloys. When electric current passes through the heater, electrical energy converts to heat due to resistance. The resistance of the heater is determined by the properties and design of its material. The higher the electric current and resistance, the more heat is generated. This heat can be used to achieve the desired temperature inside or around the device. For example, a heater in an oven or water heater can be used to heat the environment it is in. This principle is widely used to produce heat in many devices.

Technical Specifications of Resistance Stone

Material: Usually made of ceramic or glass. It is preferred in industrial heating systems due to its high-temperature resistance.

Shape: Can be spherical, cylindrical, or rectangular. The choice of shape is important for heat distribution and ease of installation.

Size: Diameter ranges from 2 mm to 10 mm. Various sizes are available to suit different applications.

Power: Ranges from 1 W to 100 W. Low-power models are used for precision applications, while high-power models are preferred for large-scale industrial systems.

Voltage: Operates at different voltage levels from 12 V to 480 V. Low-voltage models are used in portable systems, while high-voltage ones are preferred in heavy industrial equipment.

Temperature Range: Operates between 0°C and 650°C. Some models with special coatings and materials can withstand even higher temperatures.

Heating Element Type: Uses nickel-chromium wire or iron-chromium-aluminum wire. Nickel-chromium wires are highly resistant to heat and have a long lifespan, while iron-chromium-aluminum wires offer a more economical alternative.

Terminals: Made of copper or brass. Copper terminals provide high conductivity, while brass terminals are more resistant to corrosion.

Protection Class: Can be IP40 or IP65. IP40 models are suitable for indoor use, while IP65 models are resistant to water and dust, making them ideal for outdoor and harsh working conditions.

Applications: Commonly used in electric heaters, laboratory equipment, plastic injection machines, food processing devices, mold heating systems, and medical devices.

Advantages: Offers high efficiency, long lifespan, low maintenance requirements, and fast heating times. Additionally, it can be manufactured in various shapes and sizes to fit different applications.

Some common heater types and their technical specifications:

- Ceramic heaters:

- Material: Aluminum oxide, silicon carbide, magnesium oxide.

- Operating Temperature: Up to 650°C.

- Resistance: Between 1.0 Ωm and 10.0 Ωm.

- Thermal Conductivity: Between 10 W/mK and 100 W/mK.

- Density: Between 3.0 g/cm³ and 4.0 g/cm³.

- Glass heaters:

- Material: Borosilicate glass, quartz glass.

- Operating Temperature: Up to 450°C.

- Resistance: Between 10.0 Ωm and 100.0 Ωm.

- Thermal Conductivity: Between 1.0 W/mK and 10 W/mK.

- Density: Between 2.5 g/cm³ and 3.0 g/cm³.

Materials Used in Heater Manufacturing

- Nickel-Chromium Alloys: The most commonly used heater material.

- Iron-Chromium-Aluminum Alloys: Resistant to high temperatures and provide electrical resistance.

- Nickel-Aluminum Alloys: Used in specific applications.

- Platinum and Gold: Can be used in precise industrial equipment.

Heater Stones Industrial Applications

- Food Industry: Heater stones are used in food processing equipment such as ovens, grills, pizza ovens, and other heating devices. These devices require precise temperature control to ensure the food is cooked or baked properly. Heater stones are essential in achieving consistent heat distribution for optimal food quality and safety.

- Plastic and Rubber Industry: In the extrusion machines, molding machines, and other process equipment used for heating plastic and rubber materials, heater stones play a critical role. They provide the necessary heat to soften the materials, ensuring they are shaped accurately and efficiently. The consistent heat also helps maintain the required viscosity for the manufacturing process.

- Chemical Industry: Heater stones are used in controlling chemical reactions, evaporators, reactors, and other process equipment that require heating. These industries often deal with high temperatures to facilitate chemical processes like distillation, polymerization, and reaction kinetics. Heater stones offer precise temperature control to ensure that the reactions take place at the desired rates.

- Packaging Industry: Heater stones are used for heating and cutting in hot cutting machines, thermoforming machines, and other packaging equipment. They ensure that materials such as plastic films are heated evenly for processes like sealing, cutting, and molding. Accurate heating is crucial for maintaining product quality and reducing material waste during packaging processes.

- Automotive Industry: Heater stones are used in furnaces and other heating equipment for thermal treatment of automotive parts. In processes like annealing, tempering, and hardening, heater stones provide the precise and controlled heating necessary for altering the mechanical properties of metal parts, enhancing their durability and performance in vehicles.

- Textile Industry: Heater stones are employed in textile machines for drying fabrics, heat-setting, and printing. In the textile industry, consistent heat is required for processes such as curing, dyeing, and finishing fabrics. Heater stones ensure that textiles are treated evenly and efficiently, improving the quality of the final product.

- Energy Production: Heater stones are used in boilers, water heaters, steam generators, and other energy production equipment. In power plants, for example, they are crucial in ensuring that water is heated efficiently to produce steam, which drives turbines to generate electricity. The ability to withstand high temperatures and provide consistent heat is essential for the reliable operation of energy generation systems.

- Medical and Laboratory Technologies: Heater stones are used in laboratory furnaces, incubators, and other lab equipment for heating purposes. In the medical and scientific fields, precise temperature control is critical for experiments, sterilization, and incubation. Heater stones ensure that laboratory equipment operates within the required temperature range to maintain the integrity of samples and processes.

Advantages of Heater Stones

- High Heat Resistance: Heater stones are generally capable of withstanding high temperatures, making them ideal for applications that require reliable performance in extreme heat conditions. This heat resistance ensures that they can function efficiently in high-temperature environments for extended periods of time.

- Rapid Heating and Cooling: Heater stones can be quickly heated and cooled, which is essential for industries where fast temperature adjustments are necessary. Their ability to respond to temperature changes promptly makes them highly efficient in time-sensitive processes.

- Long Lifespan: High-quality heater stones can last for many years, providing durable and consistent performance. Their longevity reduces the frequency of replacement, making them a cost-effective solution for industries that rely on consistent heating elements.

- High Precision: Heater stones allow for precise temperature control, which is crucial in many industrial processes that require accuracy. They help maintain the desired temperature consistently, leading to better quality products and optimized processes.

- Flexibility for Various Applications: Heater stones are versatile and can be used in a wide range of industrial applications. From food processing to automotive manufacturing, they are adaptable and efficient in different sectors, offering flexibility for diverse heating needs.

- Easy Installation and Maintenance: Heater stones are typically easy to install and maintain. Their straightforward design allows for quick setup in various equipment, and routine maintenance can be performed without much hassle, ensuring continued efficiency and performance.

Heater Stone Features for High Heat Efficiency

- Fast Heating: Heater stones quickly heat up due to their low thermal lag, efficiently converting electrical energy into heat.

- Uniform Heat Distribution: Ensures even heat spread, minimizing temperature differences and improving heating efficiency.

- High Heat Resistance: Can operate at high temperatures without deformation, ensuring long-term durability.

- Low Heat Loss: Special coatings and insulation materials minimize energy loss, increasing thermal efficiency.

Heater Stone Technical Details

- Material: Made of ceramic or glass, providing high-temperature resistance.

- Shape: Available in spherical, cylindrical, and rectangular forms, selected based on application needs.

- Size: Ranges from 2 mm to 10 mm in diameter, chosen according to the required application.

- Power: Varies between 1 W and 100 W, selected based on heating requirements.

- Voltage: Operates within 12 V - 480 V range, with lower voltages for portable devices.

- Temperature Range: Functions between 0°C and 650°C, with special coatings allowing higher temperatures.

- Heating Element: Uses nickel-chromium or iron-chromium-aluminum wires; nickel-chromium is more durable.

- Terminals: Made of copper or brass; copper provides better conductivity, while brass offers corrosion resistance.

- Protection Class: Available in IP40 and IP65; IP65 models are suitable for outdoor use.

Energy Savings with Heater Stone

- Efficient Heating: Provides maximum efficiency with minimal energy consumption due to fast and balanced heat distribution.

- Proper Power Selection: Using an overpowered heater stone leads to energy waste; the power level should be chosen accordingly.

- Insulation: Well-insulated heater stones prevent unnecessary heat loss, reducing energy consumption.

- Smart Control Systems: Automatic temperature adjustment and thermostats help prevent excessive energy use.

Technical Details to Consider When Selecting a Heater Stone

- Application Area: Must have the appropriate protection class for indoor or outdoor use.

- Operating Environment: If exposed to high humidity or chemicals, more durable materials should be chosen.

- Power and Voltage Compatibility: Must match the power and voltage values of the device it will be used with.

- Ease of Installation: Should be compatible with the required mounting and connection apparatus.

Heater Stone Working Principle

- Conversion of Electrical Energy to Heat: Internal nickel-chromium or iron-chromium-aluminum wire generates heat when electrical current flows through it.

- Heat Distribution: The produced heat is evenly distributed by ceramic or glass insulating materials.

- Temperature Control: Thermostats or temperature sensors in heating circuits maintain the desired temperature.

- Safety Mechanisms: Thermal fuses or circuit breakers protect against overheating.

Frequently Asked Questions

Ceramics for Heaters

-min-500x500w.jpg)