Heaters

From daily life to industrial production, the need for heating is essential in many applications. One of the most critical components for meeting this need is the electric heating element known as a heater. But what exactly is a heater, how does it work, and in which industries is it used?

In this comprehensive guide, you will find detailed information on the working principles, technical specifications, types, and applications of heaters.

What is a Heater?

A heater is a device that converts electrical energy into heat. Derived from the word "resistance," this term refers to the electrical resistance created by a material, which generates heat according to Joule's law. Heaters are widely used, from household appliances to industrial machinery.

Typically made of metal wires or strips, heaters produce heat when an electric current passes through them. Depending on the application, they are manufactured with different materials and coatings to achieve various temperature and durability levels.

How Does a Heater Work?

Heaters operate according to Joule’s Law:

- P = I² * R

Where:

- P (power) represents the heat generated in watts,

- I (current) represents the electric current in amperes,

- R (resistance) represents the material's electrical resistance in ohms.

The electric current passing through the heater encounters resistance, generating heat that is then transferred to its surroundings. The heater's power, resistance, and material composition vary depending on its application.

Types of Heaters

Heaters are manufactured in various types based on their application and structure. Each type has unique characteristics and advantages, making them suitable for different industrial processes. Below are the most common types of heaters and their descriptions:

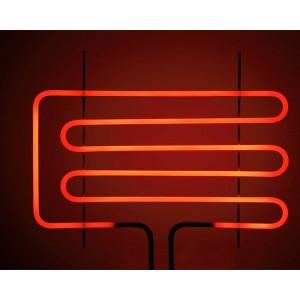

1. Wire Heaters

- One of the simplest and most widely used heater types, typically made from nickel-chromium (NiCr) alloys, providing high resistance and durability.

- Commonly found in electric stoves, toasters, and household ovens.

2. Cast Heaters

- Manufactured using casting techniques with aluminum, brass, or bronze, providing excellent durability and uniform heat distribution.

- Used in plastic injection machines and mold heating processes.

3. Cartridge Heaters

- Small cylindrical heaters designed for efficient heating in confined spaces.

- Commonly used in injection machines, laboratory equipment, and metal processing machinery.

4. Silicone Heaters

- Flexible heaters that can be applied to pipes, tanks, and irregular surfaces.

- Resistant to moisture and chemicals, making them ideal for the chemical and food industries.

5. Ceramic Heaters

- High-temperature heaters that use ceramic insulation, ensuring energy efficiency and long-lasting heat retention.

- Used in industrial furnaces and glass processing machines.

6. Tubular Heaters

- Commonly used for heating water, oil, and air in various applications.

- Typically made of stainless steel or titanium, ensuring durability and corrosion resistance.

7. Infrared Heaters

- Use infrared radiation to heat surfaces quickly and efficiently.

- Widely used in the medical industry and rapid drying applications.

Applications of Heaters

Heaters have a wide range of applications, from industrial to household use. Here are the primary application areas:

1. Household Appliances

- Water Heaters, Coffee Makers: Used for rapidly heating water to the desired temperature.

- Ovens, Toasters: Provide even heat distribution for cooking and baking.

- Electric Stoves and Space Heaters: Used for heating kitchens and living spaces.

2. Plastic and Rubber Industry

- Injection Molding Machines: Ensure uniform heating of molds for precise plastic shaping.

- Rubber Vulcanization Systems: Enhance the durability and strength of rubber products.

3. Metal Processing Industry

- Die-Casting Machines: Melt metals for shaping in molds.

- Heat Treatment Furnaces: Used for hardening or softening metal components.

4. Automotive Industry

- Battery and Engine Heaters: Improve cold-weather performance.

- Defrosting Systems: Prevent windshield icing and enhance visibility.

5. Chemical and Petrochemical Industry

- Reactor Tank Heating: Ensures precise temperature control for chemical reactions.

- Pipeline Heating: Prevents blockages and ensures smooth fluid flow.

6. Medical and Laboratory Equipment

- Sterilization Devices: Used for heating in sterilization processes.

- Blood Analysis Machines: Maintain stable temperatures for laboratory procedures.

Factors to Consider When Choosing a Heater

- Operating Temperature: Should match the environmental conditions and application.

- Power and Voltage: Must be compatible with the electrical system.

- Material Selection: Stainless steel, nickel-chromium, or ceramic for durability.

- Insulation Quality: Should prevent electrical leakage and improve safety.

- Ease of Installation: Should be suitable for the intended device or application.

Heaters

Heaters play a crucial role in converting electrical energy into heat for a wide range of industrial and domestic applications. Their various types allow for solutions tailored to different temperature and durability requirements.

If you're looking for the right heating system, selecting the appropriate heater will ensure energy-efficient and long-lasting performance.

Frequently Asked Questions

1. What is a Heater?

A heater is a heating element that converts electrical energy into heat. It generates heat by resisting the flow of electrical current.

2. Where Are Heaters Used?

They are commonly found in household appliances (ovens, heaters), industrial furnaces, metal processing machines, plastic melting equipment, and electronic devices.

3. What Are the Different Types of Heaters?

- Wire Heaters: Flexible and long-lasting.

- Cartridge Heaters: Small and cylindrical in shape.

- Silicone Heaters: Flexible and chemical-resistant.

- Ceramic Heaters: Provide high-temperature resistance.

- Tubular Heaters: Used for heating water and air.

4. What Should You Consider When Choosing a Heater?

- Operating Temperature: Should match the required heat range.

- Material Compatibility: Must suit the processing material.

- Size and Shape: Must fit the installation area.

- Energy Efficiency: Lower energy consumption is preferred.

5. What Are the Benefits of Using a Heater?

- Precise Heating: Provides localized heat efficiently.

- Long Lifespan: Made from durable materials.

- Compatibility: Works with various materials.

- Energy Efficiency: Maximizes heat output with minimal power usage.